-

Zodiac Boats

-

The CHTTC owns two Zodiac watercraft Pro 650 models comprised of a fiberglass hull, and top portion consisting of a U shaped tube made of high strength laminated rubber. The U shaped tube has 5 individual chambers allowing the boat to stay afloat if up to 2 of the chambers are punctured. The Zodiacs are 21' long, and with a width of 8'. Each is powered by a 150 hp, Yamaha outboard motor. The boats are capable of carrying 13 adult passengers, or 975kg. Both are equipped with sonar, and GPS systems.

-

-

Scale Model Horizontal Axis Hydrokinetic Turbine

-

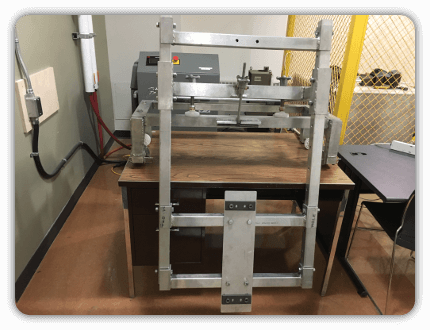

The CHTTC owns a 19.8 cm diameter scale horizontal axis hydrokinetic turbine. The model turbine consists of a rotor blade attached shaft coupled to a vertical shaft by a right angle 1:1 bevel gearbox. The turbine is supported by flat bars in a V-shape to increase the stability and eliminate vibrations when operating in high flow velocities or at high shaft speeds. The turbine shaft and flat bars are attached to a baseplate to secure the instrumentation. Above the baseplate a transducer, which measures torque and rotational speed, is attached to the turbine shaft on one end and on the opposite end to the shaft of a DC motor.

-